-

Titanyum Boru Ek Parçaları

-

Titanyum Kaynaklı Boru

-

Titanyum Boru Flanşı

-

Dikişsiz Titanyum Boru

-

Titanyum Eşanjör

-

Titanyum Bobin Borusu

-

Titanyum Alaşımlı Levha

-

Titanyum Bağlantı Elemanları

-

Titanyum Kaynak Teli

-

Titanyum Yuvarlak Çubuk

-

titanyum dövme

-

Titanyum Kaplı Bakır

-

titanyum elektrot

-

Metal Püskürtme Hedefi

-

Zirkonyum Ürünler

-

Sinterlenmiş Gözenekli Filtre

-

Şekil Hafızalı Nitinol Teli

-

Niob Ürünleri

-

Tungsten Ürünleri

-

Molibden Ürünleri

-

Tantalum Ürünleri

-

Ekipman Ürünleri

-

alüminyum ürünler

-

Paslanmaz çelik ürünleri

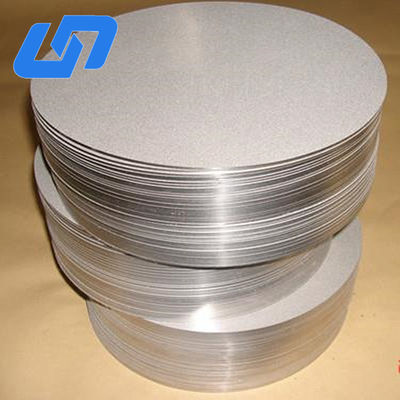

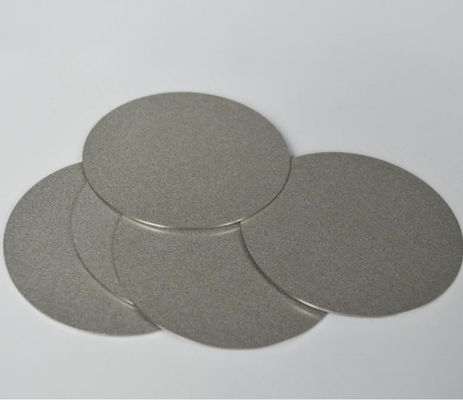

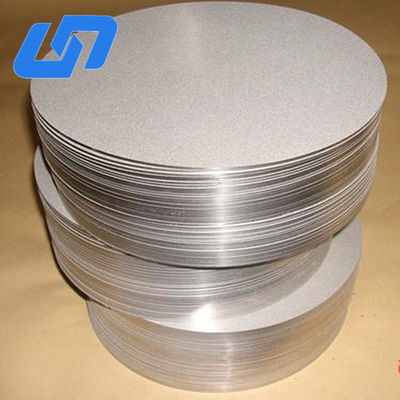

Sintered Plate Inconel600 Titanium SS 316L For Filtration And Separation

| Menşe yeri | ÇİN |

|---|---|

| Marka adı | CSTY |

| Sertifika | GB/T19001-2016/ISO9001:2015 |

| Model numarası | SS 316L |

| Min sipariş miktarı | 10kgs |

| Fiyat | $80.00 - $110.00/ Piece |

| Ambalaj bilgileri | film ve tahta sandık, karton Ambalaj müşteri ihtiyaçlarına göre olabilir. |

| Teslim süresi | 15 ~ 20 İş günü |

| Ödeme koşulları | L/C, T/T, Western Union, MoneyGram, PayPal |

| Yetenek temini | Ayda 5000 Kilogram/Kilogram |

Ücretsiz numune ve kuponlar için bana ulaşın.

Naber:0086 18588475571

sohbet: 0086 18588475571

Skype: sales10@aixton.com

Herhangi bir endişeniz varsa, 24 saat çevrimiçi yardım sağlıyoruz.

x| Filtrasyon doğruluğu | 0.1um | Aşınma direnci | Yüksek |

|---|---|---|---|

| karakteristik | Son derece aşındırıcı ortamlarda kullanılır | Filtrasyon alanı | 0.3-1.0m2 |

| Spesifikasyon | 0.5um, 2um, 5um, 10um, | Çap | 50-1000mm |

| Malzeme | Titanyum, SS 316L, Inconel600, vb. | Örnek Hizmet | Test için numune sağlayın |

| Tip | Metal, SS Filtre Diski | Standart | ISO9000 |

| Çalışma baskısı | 2-3Mpa | Paketleme | Standart İhracat Paketi |

| Hizmet ömrü | 2-5 Yıl | Maksimum basınç | 2.0mpa |

| Boyut | Özelleştirilmiş | ||

| Vurgulamak | Sinterli gözenekli Inconel600 filtre plağı,Titanyum sinterlenmiş filtreleme plağı,SS 316L sinterli ayırma plağı |

||

Introduction

Compared with traditional filtration materials such as paper, cotton, PP, PE, PES, and PTFE, metal powder sintered porous materials offer superior performance. They provide excellent permeability, precise pore size control, stable shape, high filtration accuracy, wear resistance, good mechanical strength, and excellent heat conduction and dissipation.

Moreover, sintered metal materials can withstand high temperatures, maintain their shape under stress, and be cleaned and reused multiple times, making them a durable and cost-effective filtration solution.

Specifications

| Product Name | Sintered Plate |

|---|---|

| Material | Pure Titanium / SS316L / Bronze / Inconel 600 |

| Size | OD 20–80 mm × WT 2.5–3.0 mm × L 10–1200 mm |

| Filter Accuracy | 0.5–80 µm |

| Connection | Customized according to customer requirements |

| Applications | Sparging, Separation and Filtration, Carbonation, Liquid Filtration, etc. |

Technical Parameters

| Filter Accuracy (µm) | Porosity (%) | Permeability (m³/m²·h·kPa) | Compression Strength (MPa) | Temperature Tolerance (°C) | Max Working Pressure (MPa) |

|---|---|---|---|---|---|

| 0.5–50 | 20–50 | 3–800 | 2–3 | 250 | 0.6 |

Applications

The sintered plate is widely used in industries including electronics, water treatment, food and beverage, biotechnology, chemicals, petrochemicals, metallurgy, and gas purification. It represents a new generation of filtration materials with broad development potential.

Typical applications include:

-

Sparging

-

Separation and Filtration

-

Carbonation

-

Liquid Filtration

-

Catalyst Recovery

-

Steam Filtration

-

Slurry Oil Filtration

-

Flame Arrestors

-

Sound Silencing

-

Fluid Distribution and Control

-

Semiconductor Manufacturing

-

Fuel Cell Stacks

-

Coating Electrodes

-

Damping and Shock Absorption

-

Heat Exchange

-

Bio-Implants

Properties

-

Uniform pore size and stable pore structure with high separation efficiency

-

High porosity, low filtration resistance, and excellent permeability

-

Outstanding chemical stability and resistance to acids, alkalis, and oxidation

-

Morphological stability—no particle shedding; compliant with food hygiene and pharmaceutical GMP standards

-

Strong mechanical properties, low differential pressure, and large flow capacity

-

Excellent anti-microbial characteristics, non-reactive with microorganisms

-

Easy online regeneration, backwashing, and long service life

-

Excellent biocompatibility for use in biological, food, pharmaceutical, and medical applications

-

Effective electromagnetic shielding performance

-

Strong damping and shock resistance